seal integrity testing

Seal Integrity Testing

USP 1207 and ASTM Methods for Packaging Integrity

About

Seal Integrity Testing

In industries such as pharmaceuticals, food, and medical devices, the integrity of packaging is critical. A small leak or weak seal can lead to product contamination, reduced shelf life, or even patient risk. This is why seal integrity testing has become a core element of quality assurance. By following regulatory standards such as USP 1207, ASTM F88, ASTM F2096, ASTM F2338, ASTM F1140, and ASTM D3078, companies can validate packaging reliability and meet compliance requirements.

At Cell Instruments, we provide advanced seal integrity test equipment designed to meet these global standards, offering both destructive and non-destructive methods for accurate package seal evaluation.

packaging seal integrity testing is essential for your products quality

Why Seal Integrity Testing Matters

Seal defects—whether from material flaws, improper sealing parameters, or environmental stress—pose significant risks. For medical devices, a breach could compromise sterility; for food products, it might introduce pathogens. Beyond safety, regulatory bodies like the FDA and ISO mandate rigorous testing to validate packaging reliability.

Verify packaging quality before market release

· Pharmaceutical packs may lose sterility, risking patient safety

· Food packaging can experience accelerated spoilage

· Medical devices might suffer functional compromise

· Industrial components (e.g., hydraulic seals) face operational failures

Detect leaks, weak seals, and micro-defects invisible to the naked eye

· Pharmaceuticals: Sterile barrier protection (per USP 1207).

· Food & Beverages: Extended shelf life and contamination prevention.

· Medical Devices: Maintaining aseptic conditions during storage.

· Electronics: Protection against moisture and dust.

Prevent costly recalls caused by compromised product protection

Pharmaceutical Packaging Seal Integrity and USP 1207

The USP 1207 guidance defines a framework for pharmaceutical packaging seal integrity. It emphasizes deterministic methods (such as vacuum decay and high-voltage leak detection) over probabilistic ones (like dye ingress or bubble emission). The standard provides manufacturers with validated approaches to ensure that container-closure systems maintain sterility and prevent microbial ingress.

Key USP 1207 highlights:

- Encourages non-destructive methods for efficiency and sustainability

- Supports package validation at all lifecycle stages

- Aligns with FDA expectations for patient safety

For pharmaceutical companies, adopting seal integrity test USP 1207 methods is critical for regulatory compliance.

packaging seal integrity testing is essential for your products quality

Package Seal Integrity Testing Methods

Seal integrity can be evaluated using destructive and non-destructive methods:

- Destructive Methods: ASTM F88 tensile testing, ASTM F1140 burst and creep, ASTM F2096 bubble emission, ASTM D3078 vacuum bubble testing

- Non-Destructive Methods: ASTM F2338 vacuum decay, high-voltage leak detection, tracer gas detection

Choosing the right method depends on product type, packaging material, and regulatory requirements.

Standards

Destructive Test Techniques for Seal Integrity

ASTM F88

Seal Strength of Flexible Barrier Materials

This standard measures the strength of package seals by pulling sealed materials apart until separation. It helps validate sealing processes, ensuring consistency and minimum strength requirements. Depending on package type, three techniques are used: unsupported, 90° supported, and 180° supported. While the package is destroyed in testing, it provides crucial insight into pouch seal integrity testing.

ASTM F2096

Bubble Emission Test for Gross Leaks

Known as the “bubble test,” this method detects gross leaks by pressurizing the package underwater. Continuous bubbles indicate leakage points. It is simple and effective for trays and flexible pouches, although destructive since the package is compromised once tested.

ASTM F1140

Burst and Creep Tests

Packages are internally pressurized until they burst (burst test) or held under pressure until failure occurs (creep test). This provides insight into how packages respond to transportation stress, sterilization, or pressure fluctuations. While destructive, it offers valuable data on package durability.

ASTM D3078

Bubble Emission Under Vacuum

This technique submerges packages in water within a vacuum chamber. As pressure is reduced, leaks appear as bubbles. It is widely used in flexible packaging seal integrity testing but is destructive since the package cannot be reused afterward.

NDT Leak Testing

Non-Destructive Test (NDT) Methods for Seal Integrity

ASTM F2338 – Vacuum Decay Method

This standard is the most recognized NDT method for seal integrity. The package is placed in a vacuum chamber, and sensitive pressure transducers monitor for changes that indicate leaks. It offers high sensitivity, works for both rigid and semi-rigid packaging, and preserves the tested package. Because of its reliability, it is recommended in USP 1207 as a deterministic test method for pharmaceutical packaging seal integrity.

Other Deterministic NDT Methods

Beyond ASTM F2338, non-destructive methods include:

- High-voltage leak detection for liquid-filled containers

- Tracer gas (helium) leak detection for ultra-sensitive applications

- Optical and mass spectrometry techniques for research and development

These NDT methods align with modern regulatory expectations and allow for repeatable, validated, and non-invasive testing, making them especially valuable for pharmaceutical and medical device packaging.

lab leak testing machine

Advanced Seal Integrity Test Equipment

Choosing the right seal integrity test equipment is essential for meeting compliance requirements such as USP 1207, ASTM F88, ASTM F2096, ASTM F2338, ASTM F1140, and ASTM D3078. Cell Instruments provides a complete range of solutions to support both destructive and non-destructive methods.

01

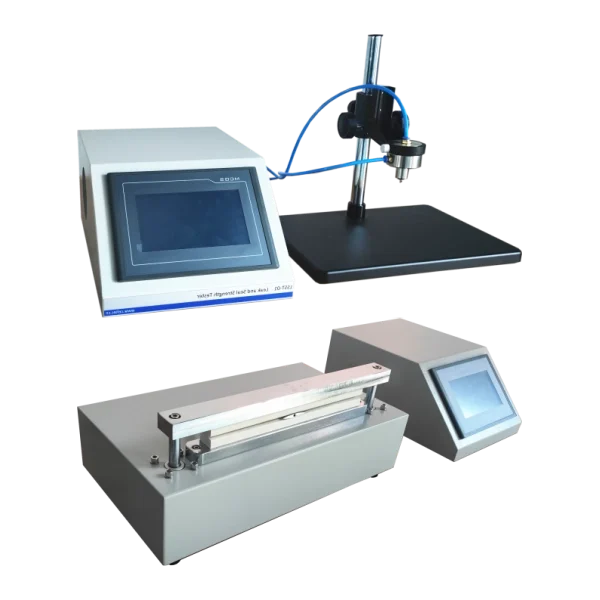

LT Leak Tester

Designed for reliable package seal integrity testing, the LT Leak Tester is widely used for leak detection in flexible and semi-rigid packaging. It complies with ASTM D3078 for bubble emission testing and is ideal for quick identification of gross leaks.

02

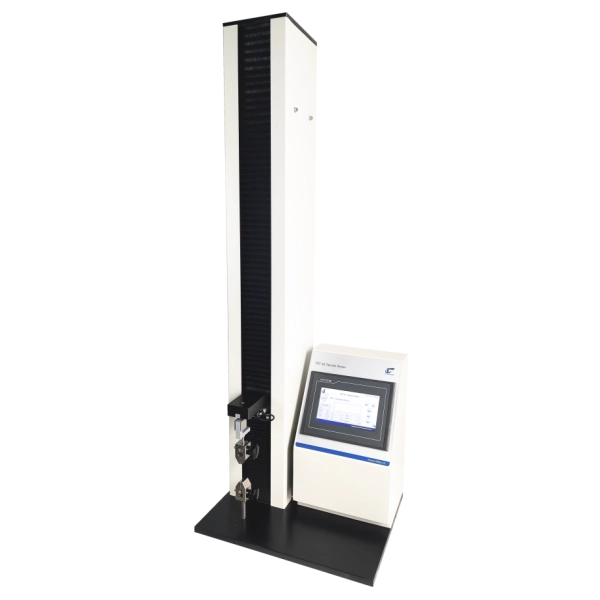

TST-01 Tensile Tester

For measuring seal strength according to ASTM F88, the TST-01 Tensile Tester provides precise, repeatable data on the force required to open seals. It is essential for verifying process validation and maintaining consistent seal strength in flexible packaging applications.

03

GLT-01 Gross Leak Tester

Suitable for ASTM F2096 bubble emission tests, the GLT-01 detects gross leaks in trays and pouches by pressurizing packages underwater. It is a reliable destructive test widely used in laboratory quality control.

04

LSST-01 Pouch Burst Tester

Perfect for pouch seal integrity testing, this instrument evaluates burst strength and creep resistance according to ASTM F1140. It simulates real-world conditions such as sterilization and transportation, helping manufacturers confirm that seals can withstand pressure differentials without failure.

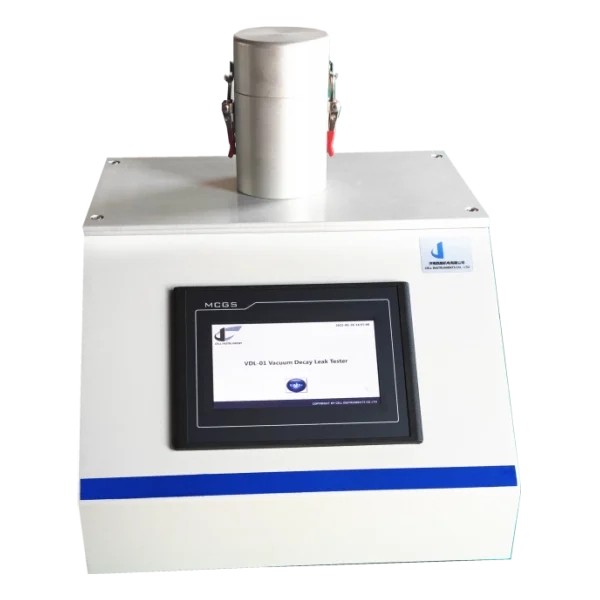

05

MLT-01 Vacuum Decay Leak Tester

Based on the ASTM F2338 vacuum decay method, the MLT-01 provides non-destructive leak detection with high sensitivity. It is particularly suitable for pharmaceutical packaging seal integrity, ensuring compliance with USP 1207 deterministic methods. This system is recommended for applications where sterility must be preserved and repeated testing is required.

By integrating both destructive and non-destructive seal integrity testing methods, Cell Instruments ensures manufacturers have the right tools for process validation, quality control, and regulatory compliance. Our instruments are designed for packaging engineers, pharmaceutical quality teams, and food safety laboratories seeking reliable and standard-compliant results.

– Cell Instruments

Get in touch

No. 5577 Gongyebei Rd, Licheng, Jinan, 250109, Shandong, P.R.C.

marketing@celtec.cn

+86 185 6001 3985